JÄGER Business Blog

with intelligent product design

WHITEPAPER

Find out which factors influence your SOP!

Geometry changes reduce material requirements

The first starting point is the geometry of a component. Machine components are often optimized for their primary purpose, not for secondary factors such as weight or material usage. With intelligent product design, it is possible in many cases to develop geometries that still meet the requirements of the application area and also cause significantly lower CO2 emissions.

For example, Jäger received a customer request for a sealing option to be used in control cabinets. It was a convex, cylindrical component that needed to be fitted with an external flat gasket to protect it against dust and moisture.

Our proposed solution was to revise the geometry of the component and integrate the seal into the component. The new combination element had a concave geometry with comparable electrical and mechanical properties, but a significantly lower material input.

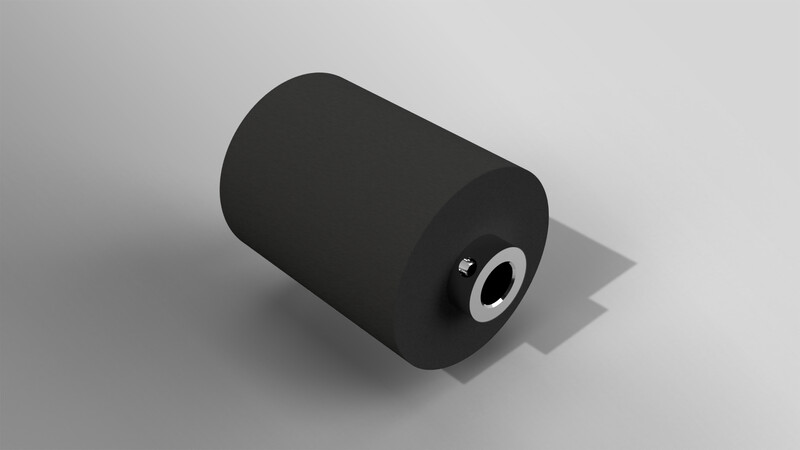

Another example can be found in one of our case studies. A few years ago, we redesigned a conveyor roller for one of our customers that originally consisted of a rubber-metal element, with a steel core and a solid rubber sheathing. Jäger developed an alternative component for this: a spoke construction made of plastic (hollow inside), which is enclosed with a much thinner rubber layer.

Both components have comparable properties. However, the new development is much lighter and uses less material.

Jäger pressure roller for conveyor belts in old and new design

Material savings like these have several effects that have a positive impact on a manufacturing company’s CO2 balance sheet:

Different types of plastics and elastomers differ in terms of the CO2 emissions generated during their processing. Silicones, for example, have to be reheated, which leads to longer heating times and thus higher energy consumption. In principle, therefore, a change of material can have a positive effect on the CO2 footprint.

On the other hand, the selection of the appropriate material depends primarily on the operating conditions of the component. Once the requirements in terms of abrasion, Shore hardness, temperatures, static or dynamic loads and chemical resistance have been taken into account, there is usually little room for optimization for a potential CO2 reduction.

A better approach is therefore to ensure that the material has the longest possible service life. The more often a component is defective, the more often it has to be replaced and disposed of. This is a significant factor in the elastomer sector in particular, since rubber, unlike plastics and metals, can hardly be recycled. Extending the service life of a component can therefore significantly improve its CO2 balance.

To this end, the design should select a material that exceeds the requirements of the application scenario. For cost reasons, the choice usually falls on a material that just meets the requirements, which is reflected in higher wear effects in the long run.

If a component has to withstand 150° C, for example, a material is often used that is designed for precisely this temperature. The thermal load on the component is correspondingly high, as it is always operating at its limit. If instead the design chooses a material that only reaches its limits at 180° C, the load is lower.

However, this is the optimum case. In practice, high-quality and thus more expensive materials are often out of the question because the company is in a competitive situation and can only increase the manufacturing costs of its products to a limited extent.

Here it is important to find a compromise between price and sustainability. Depending on the positioning of the company, it may make sense to rely on more durable but more expensive materials and to communicate this openly.

If a company purchases combined rubber or plastic assemblies from one manufacturer, there are further opportunities for CO2 reduction. In this case, the supplier can better coordinate individual elements and realize synergy effects. This can have various effects, depending on the assembly. Conceivable effects include material savings, shorter heating times or reduced transport distances.

For example, let’s look again at the cylindrical seal option. In parallel with the geometry change already described, Jäger has also combined the part and the external flat gasket. The flat gasket is now integrated into the component. At the bottom of the part, there is an annular recess into which the gasket is inserted. This not only makes assembly easier, but also requires less material because the flat gasket is smaller than before. It no longer has to cover the entire bottom surface of the component, but only the area where the component comes into contact with the board.

This improvement was only possible because a single partner took over the entire production and development of the combined assembly.

There are also opportunities to improve a company’s CO2 footprint in the area of product development. In the case of rubber and plastic articles, the geometry of the component and the choice of materials in particular harbor potential for optimization.

For example, a slightly modified design can often reduce the weight of a component as well as its material consumption, which in addition to the direct effects also reduces transport-related CO2 emissions. Choosing an alternative material can significantly increase the service life of the component, which means it needs to be replaced less frequently. And in the case of combined assemblies, it makes sense to source everything from a single source in order to realize design-related synergy effects and thus CO2 savings.

Individually, each of these factors may have only a small impact on CO2 emissions. But in large quantities, the improvements do make themselves felt, as the consumption of CO2 per item adds up. In this way, companies can make a contribution to combating climate change even with small changes

Whitepaper: Secure the Start of Production

Learn which factors influence your SOP!

Robert Gurka is a field service representative at Jäger, responsible for customers in the area from Hanover to Göttingen, as well as some key customers. He has more than 40 years of professional experience in the rubber and plastics sector.

Share post now!

Thomas van der Wardt

Petra Dirlenbach