Customized solutions for your idea

We are experts in the industry-specific development and production of rubber and plastic products as well as various material combinations. Our team of engineers and process specialists with over 500 years of experience in material, product and process development will accompany you through all phases of the product creation process – from the concept and development phase through to the series and discontinuation phase of your products.

The earlier we are involved in your developments, the better we can support you with our expertise in rubber, silicone and plastics and, for example, develop target price-oriented material and process variants.

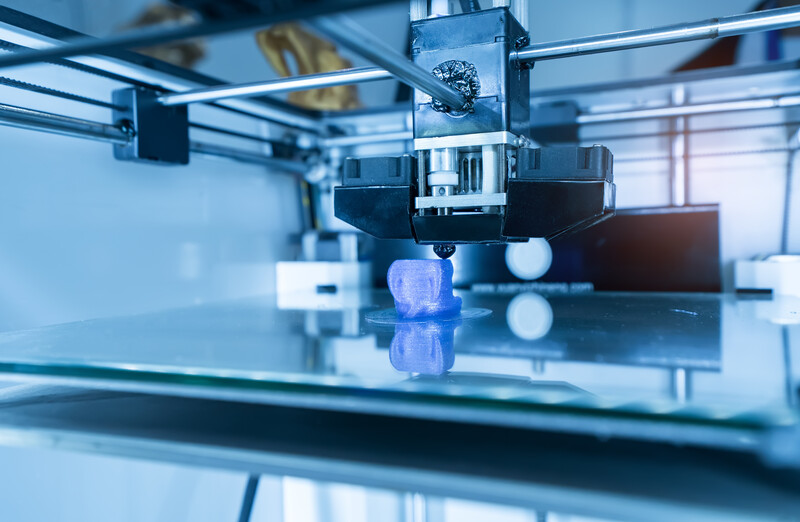

In order to offer you optimum added value in terms of quality, cost efficiency, product efficiency increases or development speed, we use all common simulation, prototyping and testing methods such as FEM calculations, 3D prototyping, mold flow analyses, static and dynamic service life tests, durability tests, etc.

Our customers’ C-parts are our A-parts: What makes us unique? As part of our product, material and process developments, we also optimize our customers’ parts from a CO₂ point of view and thus help our customers to actively achieve their CO2 targets – we know the CO₂ use for every part we develop and manufacture.

Analysis & consulting

As material and process specialists, we listen carefully to find the ideal production process and enable time, resource and cost savings.

Technical application development

Efficient testing for production-ready implementation with proactive error detection saves time and money.

Depending on the material, quantities and tolerances, we design the tool and minimize the total cost of ownership.

Material development

We pay close attention to the development of international standards and proactively develop our materials further. This enables us to provide our customers with tried-and-tested, certified materials for their individually developed products.

Industry knowledge

We focus on growth industries.

Our industry management understands the specific requirements and offers our customers corresponding added value.

Project management

Structured project management enables clear insights into every step and a successful product launch.

Material & energy efficiency

Make more out of less!

Taking longevity and repairability into account at the same time. We optimize the CO2 footprint of your components within the framework of DIN ISO 14001 and 50001, thus supporting our customers’ ESG goals.

Prototypes

Prototype production from the first ideas enables tests in pre-series status. Application-oriented test benches in our technical center supplement complex field tests and save time and money.

Simulation

We use finite element analysis (FEA) to estimate component behavior under load. Moldflow analyses are the basis for tool design in order to achieve dimensionally accurate parts with minimum cycle times.

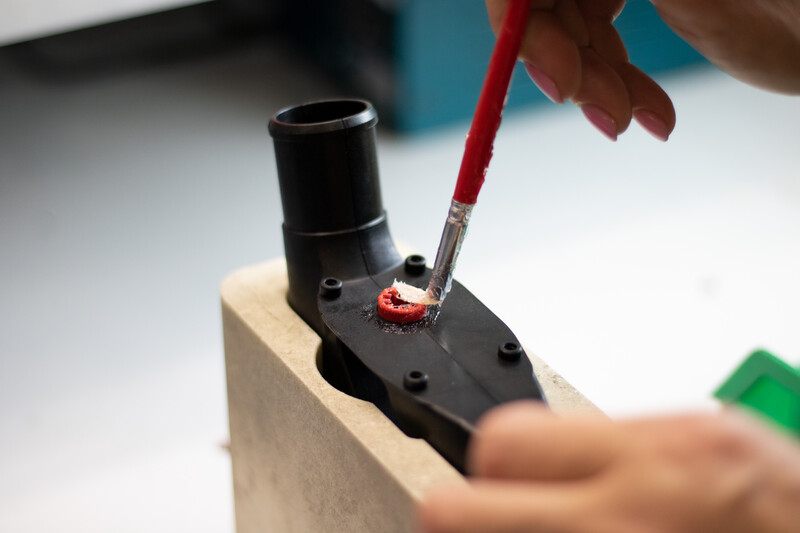

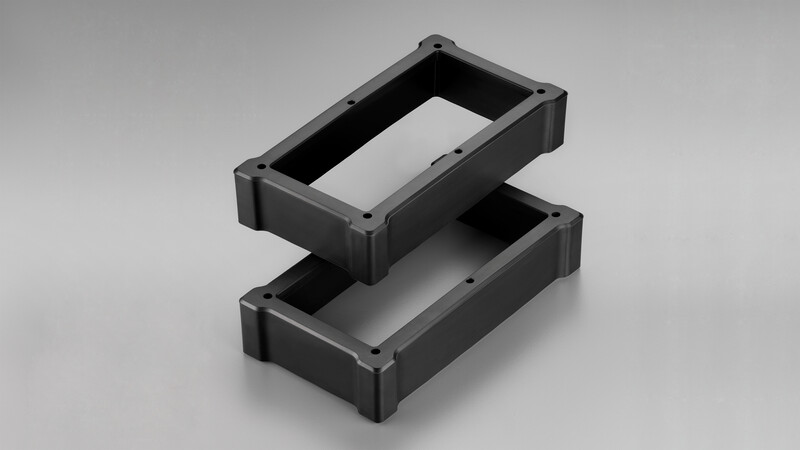

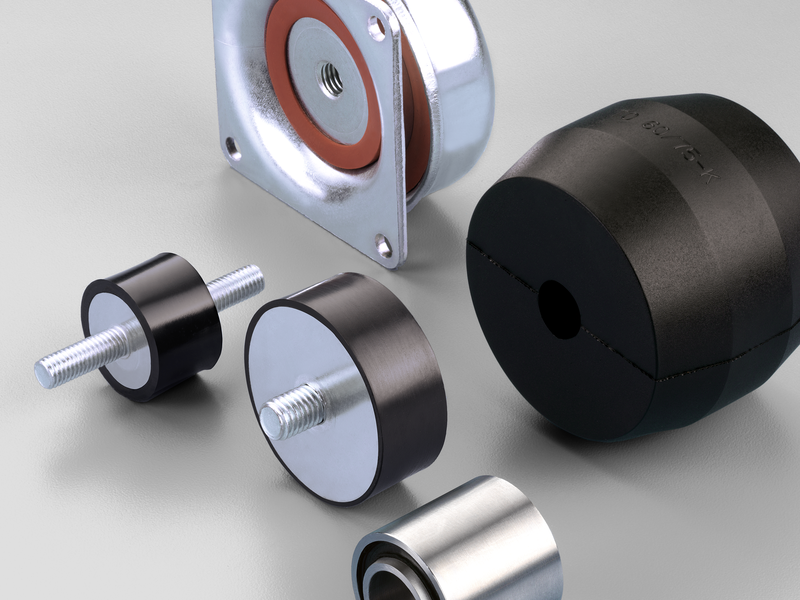

We manufacture your molded rubber parts to the highest quality standards according to your specifications. At our various production sites worldwide, we have access to over 26 compression and transfer molding machines with maximum clamping dimensions of up to 700 x 700 mm and clamping forces of up to 3,500 KN.

Our 17 injection molding machines with max. clamping dimensions of up to 1,000 x 1,200 mm and clamping forces of up to 10,000 KN complete our machine park in rubber moulding production.

Moderne Flüssigsilikon-Spritzgießmaschinen (bis 3.000 KN) inkl. professioneller Kaltkanaltechnik ergänzen unser Prozessportfolio an unserem deutschen Hauptstandort. Die Fertigung von Formteile aus Feststoffsilikon (HTV) ist ebenfalls integrativer Bestandteil unserer Prozesslandschaft.

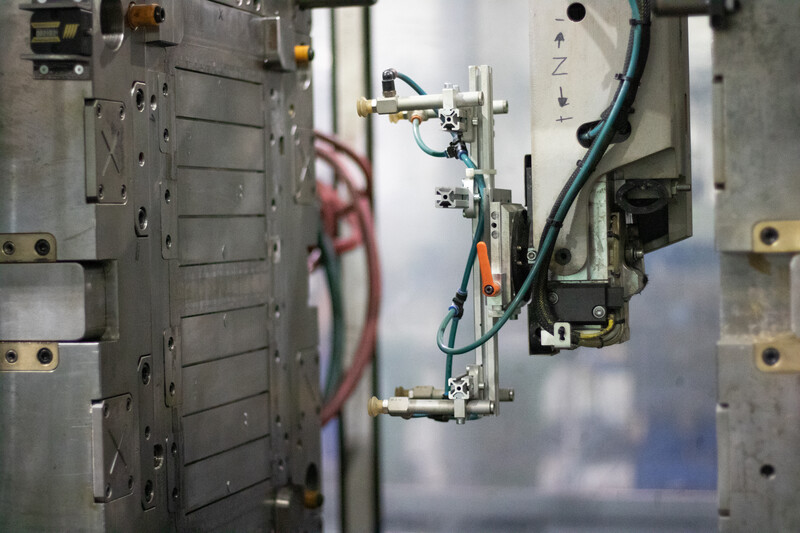

Mittels Injection Molding stellen wir Ihre Kunststoffformteile nach kundenspezifischer Zeichnung oder CAD-Daten her. Durch die einzigartigen Eigenschaften von Verfahren und Werkstoff können komplexe Geometrien realisiert werden. Mit weltweit 14 Maschinen mit Schließkräften von bis zu 4.500 KN, Entnahme- und Montagerobotern, verfügt Jäger Gummi und Kunststoff GmbH über modernste Fertigungskapazitäten. Anforderungsprofile bis zu 25.000 KN können wir mit unseren Produktionspartnern abwickeln.

As a manufacturer and supplier, we are aware of our responsibility to design and produce every process and every component as sustainably and energy-efficiently as possible. This is why we support you both in the development of new components and in the ongoing optimization of existing series in order to identify and exploit the corresponding potential. This not only saves energy and CO2, but also costs!

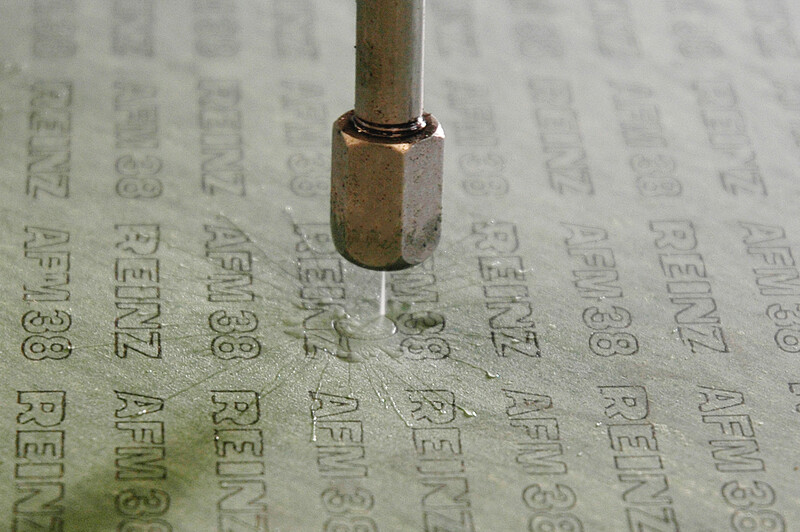

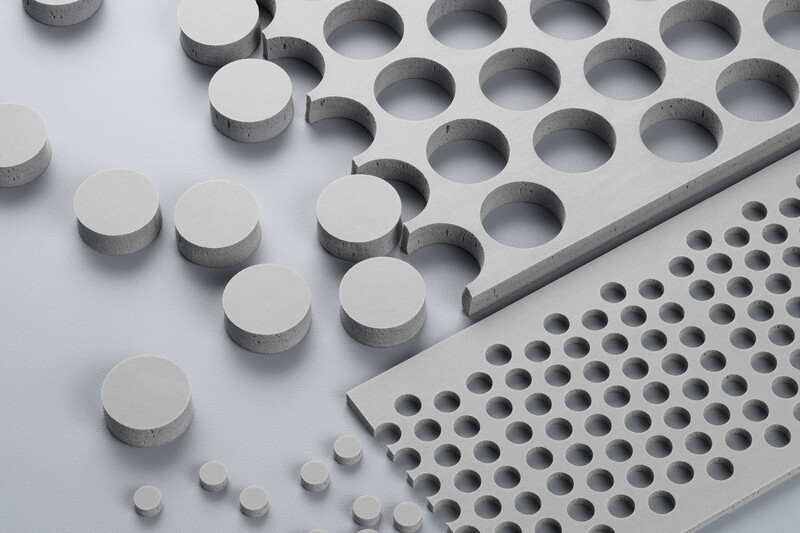

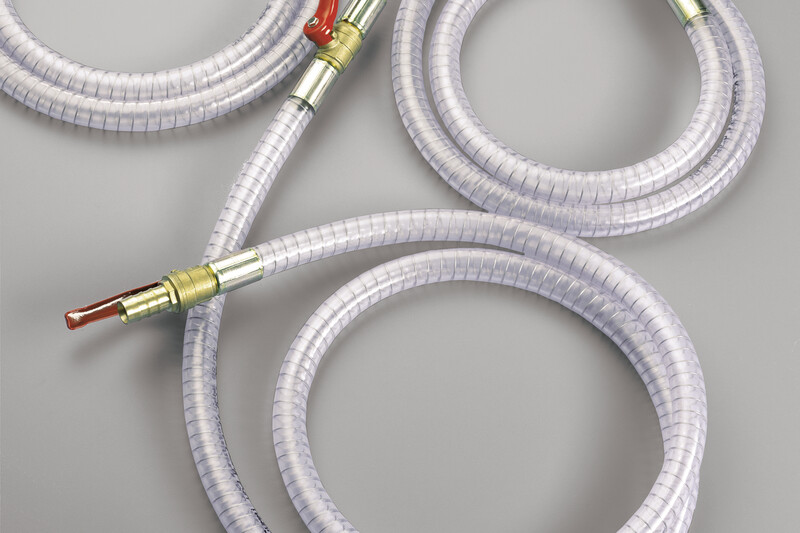

We provide you with comprehensive support in the development and production of die-cut parts and blanks. Whether you want to manufacture your products with the highest precision using classic punching or plotting, or whether you want to cut materials on a carrier film using the gentle kiss-cut process, we offer the right solutions. In addition, waterjet cutting enables the precise separation of materials without the need for special tools.

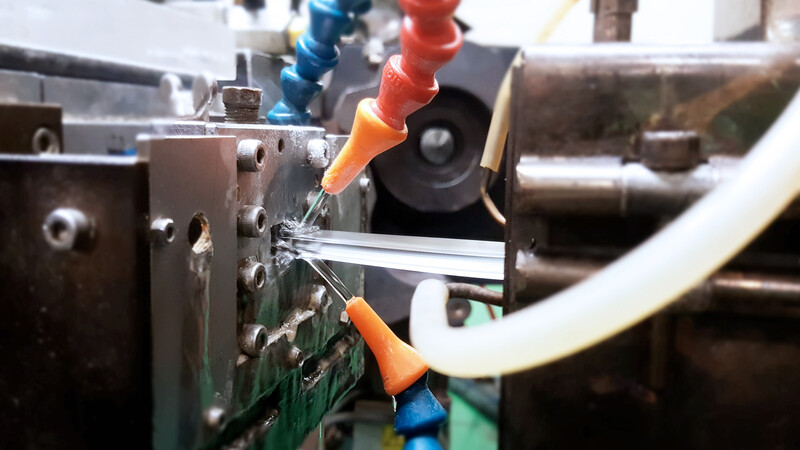

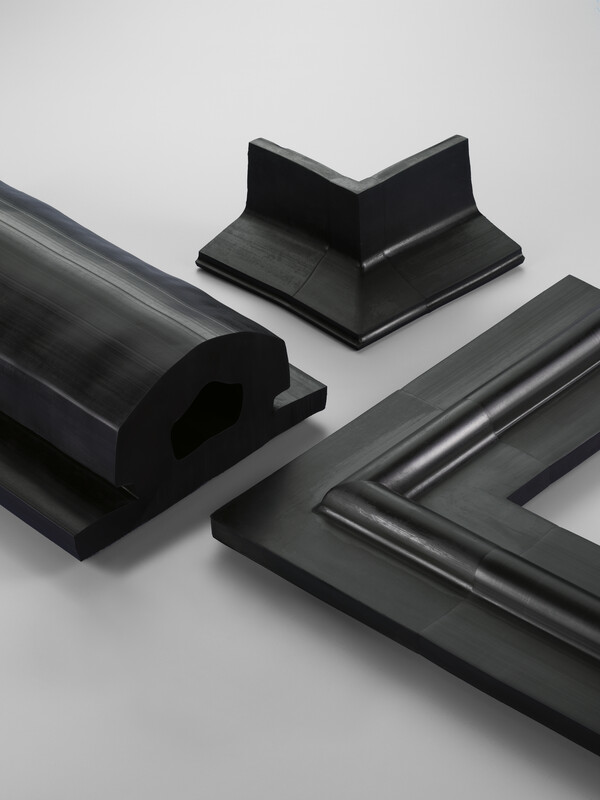

We offer you comprehensive support in both the development and production of profiles and components with a continuous shape. We take into account the special material properties of rubber and plastic, as the mouthpiece must be perfectly designed in order to achieve the desired material geometry. In addition to the development of single-component articles, two- or multi-component products are also possible.

To avoid costs in the subsequent assembly process, we can customize your products immediately after the production process on request. Whether it’s film or corner vulcanization, cutting components to length or incorporating self-adhesive properties – you save time and money by adapting the products directly to your application. We will be happy to examine your current process and offer you suggestions for optimization.

Thanks to our many years of experience, we can help you select the optimum materials for new products. At the same time, we continuously review current product series for their potential to improve properties, save costs and promote more sustainable production. The aim is to achieve optimum interaction between the areas of procurement, development and production.

Our product and process development team provides you with comprehensive services for the development of new products and assemblies. In addition to the use of CAD applications, FEM calculations and mold flow analyses, we offer comprehensive prototype construction using 3D printing processes. This enables us to check the material geometry together with you before a tool is manufactured and then optimize it.

Products

Case Study

In the further development of larger systems, small components can often only be considered to a limited extent. In the area of conveyor belts, however, there is enormous potential for savings through the methodical optimization of rubber pressure rollers.

Case Study

Products with highly specialized materials and tight tolerances are used in electromobility. Development often takes place under enormous time pressure, which is further increased in this customer project by the additional production of 13 tools.

Case Study

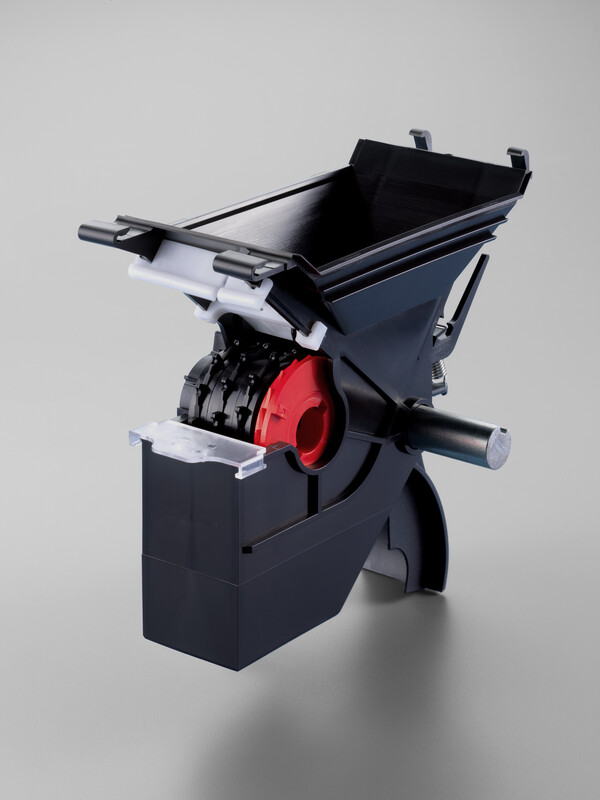

The collection of waste places high demands on the equipment of waste disposal companies. However, the exceptional damping and insulating properties of rubber components mean that sensitive components can be effectively protected.

Case Study

Rubber spring elements for damping vibrations are essential components of many agricultural machines. Targeted material adaptation makes it possible to efficiently reduce the energy and material requirements in the production of these components.

Sie haben noch Fragen oder benötigen weitere Informationen?

Kein Problem!

Füllen Sie einfach unser Kontaktformular aus. Unser Team wird sich umgehend mit Ihnen in Verbindung setzen, um alle Ihre Anliegen zu klären.

Thomas van der Wardt

Petra Dirlenbach