JÄGER Business Blog

WHITEPAPER

Find out which factors influence your SOP!

Rubber is a versatile material that is suitable for a wide range of industrial applications due to its chemical and physical properties. This versatility results, among other things, from the fact that a rubber compound is a complex mixture of several components, each of which can significantly influence the properties of the vulcanizate. Finding the one compound that meets every vulcanizate requirement is often a challenge, because optimizing one factor can negatively affect the others. Therefore, manufacturing companies should not underestimate the complexity of material selection in the rubber sector.

A rubber compound consists of a variety of raw materials and additives that have a significant influence on both the processing and the properties of the final product. In addition to the rubber, these include fillers, plasticizers, the cross-linking system, processing aids and various additives (see Table 1).

| Component | Effect on the properties |

|---|---|

| Rubber | Basic properties (temperature behavior, chemical resistance, elasticity, …) |

| Filler | Hardness, strength, abrasion, electrical conductivity |

| Plasticizer | Hardness, workability, elongation at break |

| Cross-linking system | Vulcanization speed, dynamic and static behavior |

| Processing aid | Flow behavior, demouldability, processing behavior |

| Additive | Color, extrudate stability, ageing behavior, electrical conductivity, … |

Table 1: The most important components of a rubber compound and their effect on the properties of the vulcanizate.

The basic component of every rubber compound is the polymer, the rubber, which determines basic properties such as temperature behavior, chemical resistance or elasticity.

When putting together a rubber compound, the manufacturer has a variety of synthetic rubbers at his disposal in addition to natural rubber, each of which has specific properties. Some rubbers, for example, offer excellent oil resistance, others impress with outstanding mechanical properties, and still others with very high ageing resistance. For most applications, there is a suitable rubber that offers the desired properties.

Besides rubber, fillers (e.g. carbon black, silicic acid or chalk) make up the largest proportion of a rubber compound. Among other things, they influence the hardness, strength, abrasion and electrical conductivity of the vulcanized rubber. Plasticizers also influence the hardness and workability of the compound, but also the stretchability. Although the cross-linking system makes up only a small part of the rubber compound, it has a great influence on its properties. It primarily controls the speed of vulcanization, but also influences other characteristics such as tear resistance. Processing aids influence the handling of the rubber compound during the production process. These include, for example, tackiness and flow behavior, i.e. how easily the compound can be pressed into a mold. In addition, there are a large number of other additives that influence, among other things, the color, the extrudate stability, the ageing behavior and the electrical conductivity of the rubber compound.

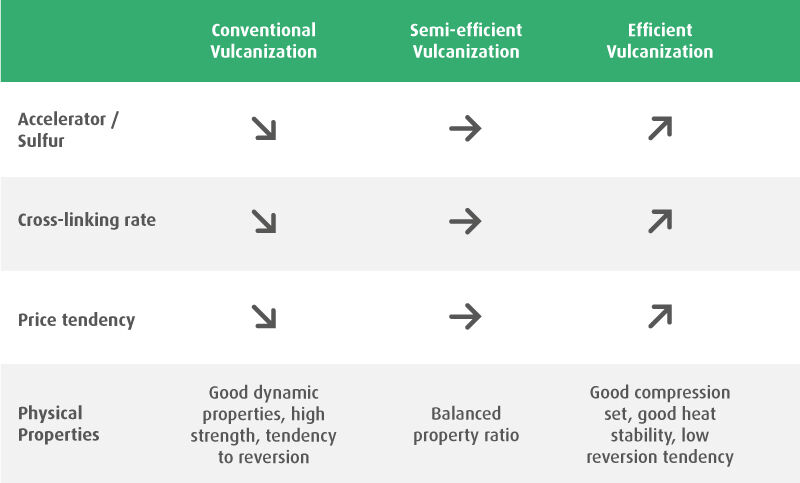

The classic crosslinking component for vulcanization is sulfur. However, pure sulfur is not very efficient for crosslinking. Therefore, in practice, accelerators are added to it to activate it and ensure that it is sensibly incorporated into the polymer chain. Depending on the ratio between sulfur and accelerator, a distinction is made between three types of vulcanization:

All three approaches differ in terms of cost, crosslinking speed and physical properties of the vulcanizate (see Figure 1).

Conventional vulcanization uses a lot of sulfur and little accelerator. This method is characterized by good dynamic properties and high strength. It is also somewhat less expensive than the other two types of vulcanization. A disadvantage is a certain tendency to reversion, i.e. if the vulcanization process is too long, the properties deteriorate, which in turn affects the production process.

In contrast to conventional vulcanization, efficient vulcanization uses more accelerator and less sulfur. This increases the crosslinking speed, while the tendency to reversion decreases. This type of vulcanization is characterized by good compression set and high heat stability. However, the cost is somewhat higher, as accelerators are more expensive compared to sulfur.

In practice, a hybrid approach is often used, i.e. a balanced ratio of sulfur and accelerators, as this approach has no significant weaknesses. This is a clear advantage in practice, since one usually has to consider a large number of different requirements here.

In our Case Study, you can learn what intelligent material selection can achieve in practice.

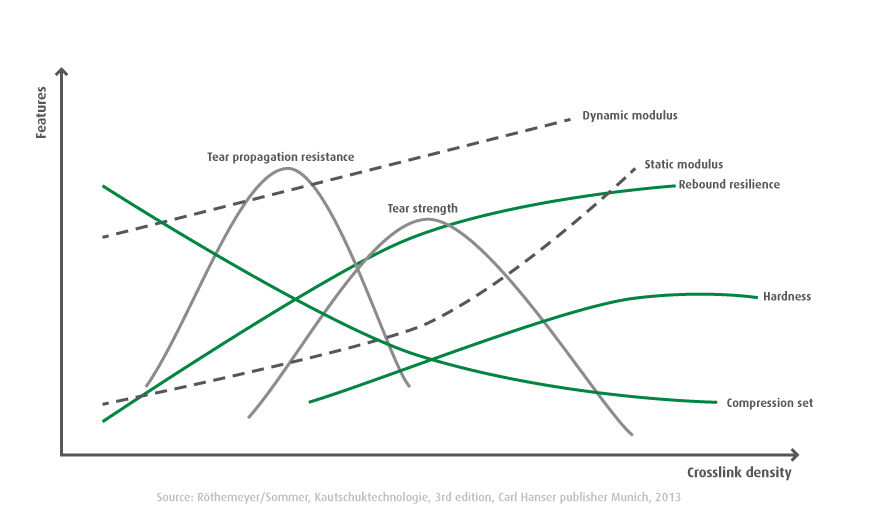

In addition to the ratio between the two components, the pure amount of crosslinking chemicals is also relevant, because the properties of the vulcanizate also change with the number of crosslinking points per unit volume (see Fig. 2). If the crosslink density increases, both hardness and elasticity increase, while properties such as compression set decrease. Other aspects such as tensile strength, on the other hand, do not develop linearly. They initially increase, then reach a maximum and decrease again as the crosslink density continues to increase. For this reason, it is important to adapt the amount of crosslinking system exactly to the general conditions. In this context, “a lot helps a lot” does not apply and may even prove harmful.

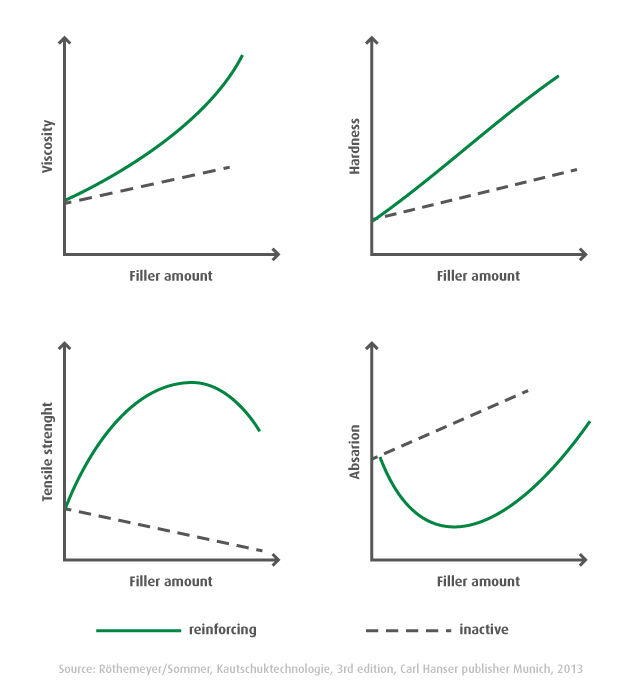

Another important component to consider in the context of material selection is the filler system. Here we distinguish between active (or also reinforcing) and inactive fillers:

An overview of the influence of active and inactive fillers on viscosity, hardness, tear strength and abrasion of a vulcanizate can be taken from Figure 3.

In addition to the base materials rubber and sulfur, there are a large number of other components that go into the production of a vulcanizate. Each of these materials has a different effect on the properties of intermediate and end products. Through interaction between the components, they collectively form a web of influencing factors, the complexity of which manufacturing companies should not underestimate.

Finding a mix that meets all requirements is often a challenge, because optimizing one factor can have a negative impact in other areas. The principle of “a lot helps a lot” therefore does not apply in rubber production. Instead, companies should make sure to focus on the properties of the finished product as early as the material selection stage. Intelligent decisions at this early stage pay off in the long run.

Whitepaper: Secure the Start of Production

Learn which factors influence your SOP!

Our compounding expert Dr. Robert Zahn completed his doctorate at Leibniz University in Hanover, Germany, in cooperation with the German Institute for Rubber Technology e.V. (DIK). His focus was on elastomer chemistry and rubber technology. He has been working for Jäger at the Hanover location since 2017 in product and process development for the area of material development.

Share this post!

Thomas van der Wardt

Petra Dirlenbach