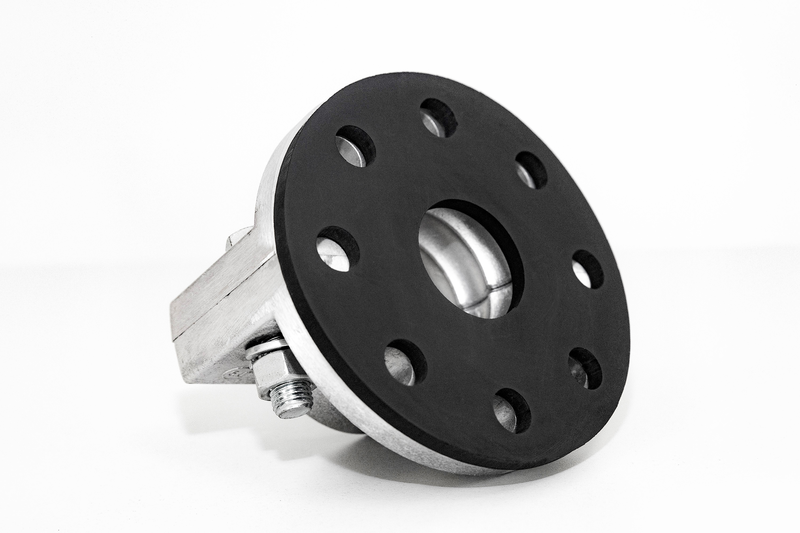

Innovative design meets functionality: focus on molded plastic parts

Quick facts plastic molded parts

Application

Materials

PA, POM, PET, PC, PPE, PVC, PE, PP, PEEK, PPS, PSU, PUR, TPE, ABS, PC/ABS, PBT, …

Manufacture

Injection molding, blow molding, foaming, thermoforming

Max. Injection weight (in-house production)

Max. Locking force (in-house production)

Quantity

Colors

RAL colors

| Application | Insulating, decorating, connecting, stiffening, etc. |

| Materials | PA, POM, PET, PC, PPE, PVC, PE, PP, PEEK, PPS, PSU, PUR, TPE, ABS, PC/ABS, PBT, ... |

| Manufacture | Injection molding, blow molding, foaming, thermoforming |

| Max. Injection weight (in-house production) | up to 2,000 g |

| Max. Locking force (in-house production) | up to 450 t |

| Quantity | on request |

| Colors | RAL colors |

Discover our range of products now!

You will find a wide range of high-quality products here – the right solution for every challenge.

Request a free sample now

Get your desired product sample free of charge by filling out our request form. Our team is happy to help!

Storage of additional components

Simultaneous development

Blog

Rubber production is an energy-intensive process. Therefore, you should already proceed intelligently and methodically with the material selection.

Blog

Whether metal or plastic – particularly strict requirements apply to materials in the food sector. Find out more on the Jäger blog!

Blog

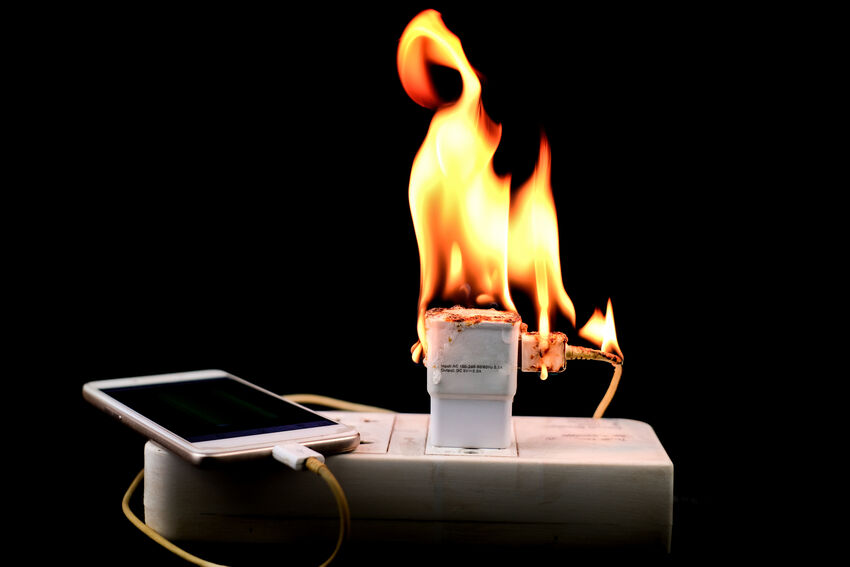

Fire protection is an important topic in the plastics and rubber sector. In particular, companies should be familiar with the two standards UL94 and DIN EN45545.

Blog

In sealing technology, it is essential to know the practical framework conditions- from application temperature to legal requirements.

Thomas van der Wardt

Petra Dirlenbach