Material combinations for demanding applications

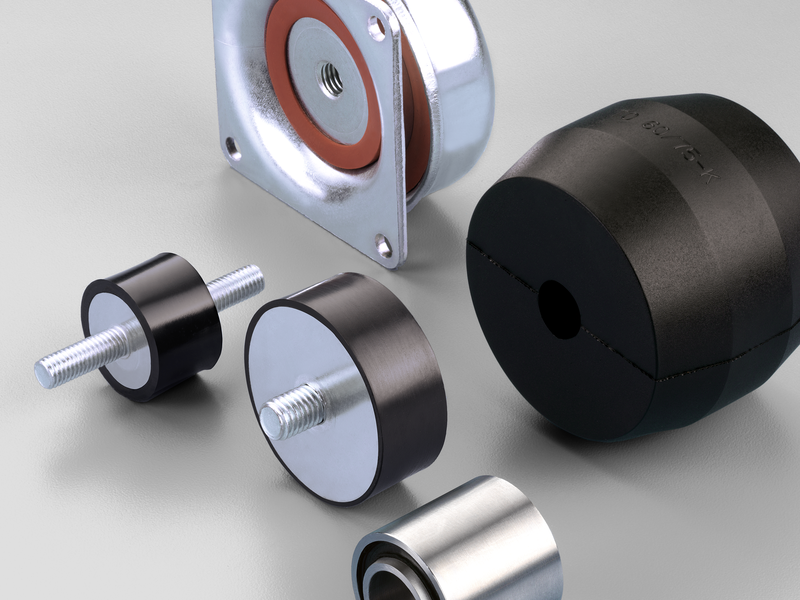

Standardized, or specially adapted to your requirements. Rubber-metal elements are essential for the production of vibration dampers, stop and rubber buffers, machine feet and other rubber-metal products. Vibration damping and noise reduction. They are used in the automotive industry, mechanical engineering and construction for vibration damping and noise reduction and construction to extend the service life of parts and components and increase comfort.

Quickfacts Rubber-Metal Elements

Application

Storage, decoupling, damping

Materials

NR, IIR but also e.g. EPDM, NBR, silicone, etc.

Hardness

soft (approx. 40-45 ±5 Shore A), medium (approx. 50-55 ±5 Shore A), hard (approx. 65 -70 ±5 Shore A)

Quality

Megi® & Schwingmetall®, but also alternative qualities

Standard rubber-metal buffer

Versions: A, B, C, D, E – further versions e.g. AT = “waisted”, AP = “parabolic”, K = “conical”, S = “with bead”

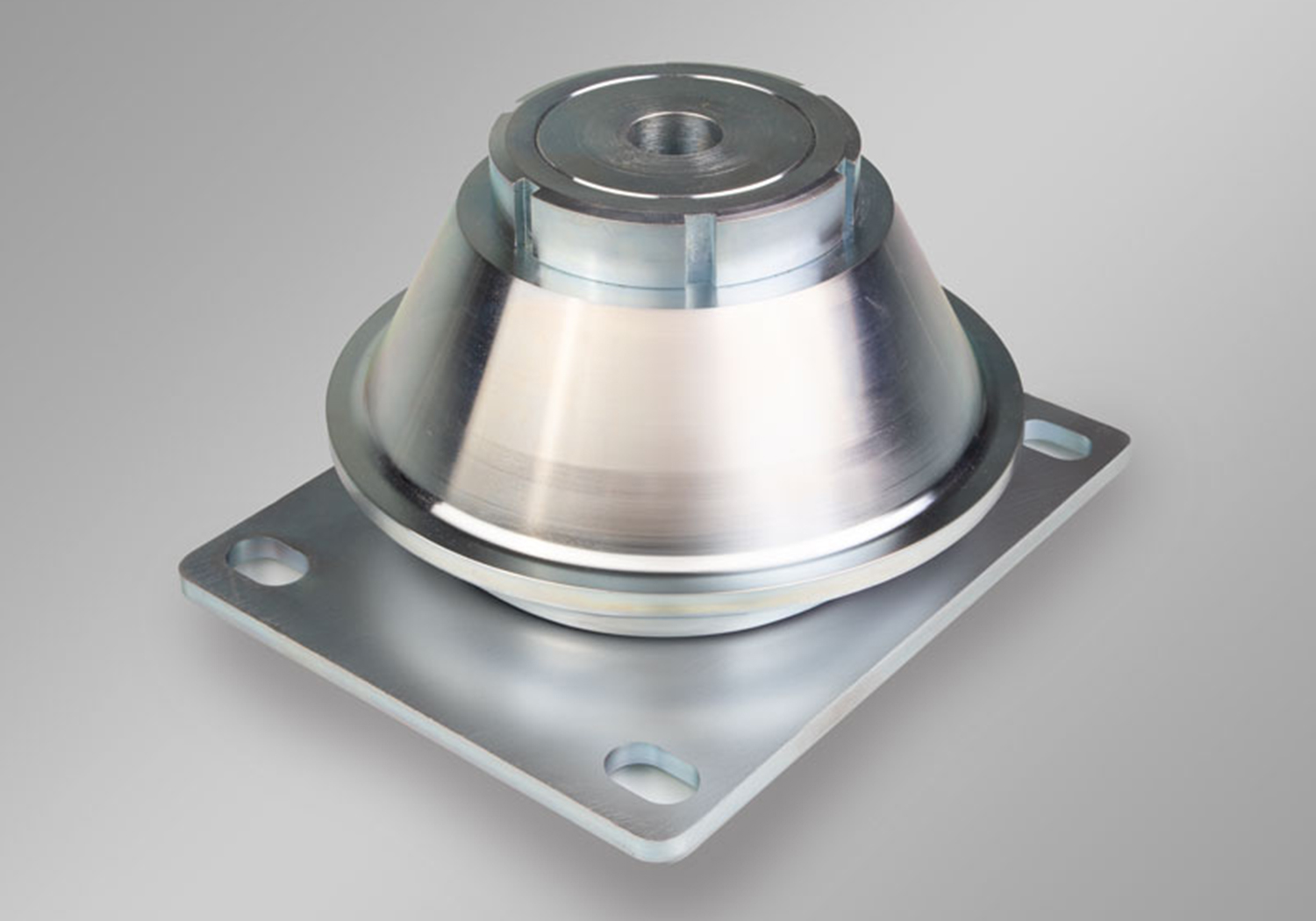

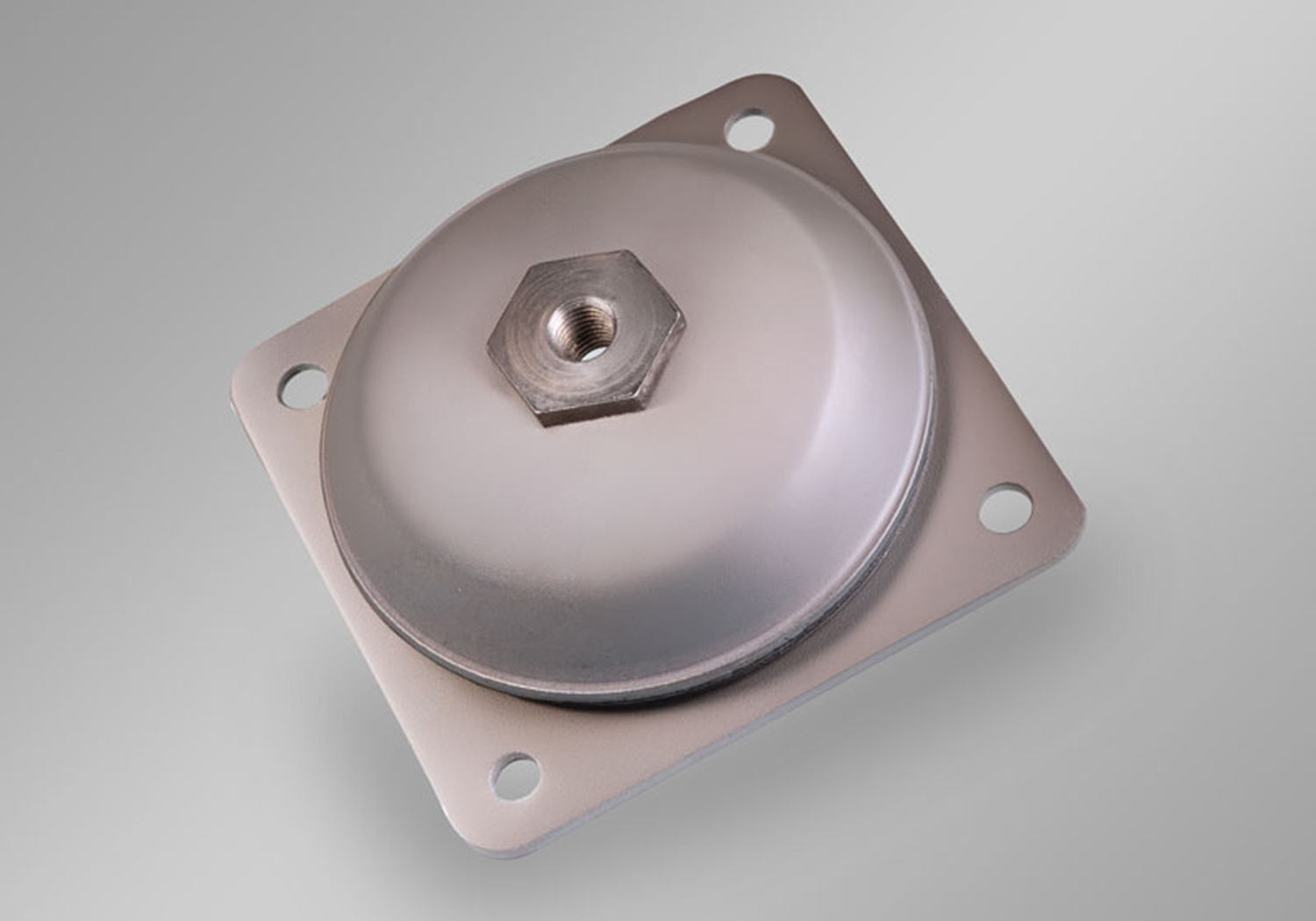

Further products

Ring buffers, conical bearings, rubber-metal rails, stop rails, U-rails, machine feet (height-adjustable, with or without breakaway protection), torsion bushings, rubber-metal hat elements, hydromounts, rubber-metal bushings, pot elements, etc.

Color

Standard: black, other colors on request

| Application | Storage, decoupling, damping |

| Materials | NR, IIR but also e.g. EPDM, NBR, silicone, etc. |

| Hardness | soft (approx. 40-45 ±5 Shore A), medium (approx. 50-55 ±5 Shore A), hard (approx. 65 -70 ±5 Shore A) |

| Quality | Megi® & Schwingmetall®, but also alternative qualities |

| Standard rubber-metal buffer | Versions: A, B, C, D, E - further versions e.g. AT = "waisted", AP = "parabolic", K = "conical", S = "with bead" |

| Further products | Ring buffers, conical bearings, rubber-metal rails, stop rails, U-rails, machine feet (height-adjustable, with or without breakaway protection), torsion bushings, rubber-metal hat elements, hydromounts, rubber-metal bushings, pot elements, etc. |

| Color | Standard: black, other colors on request |

Discover our range of products now!

You will find a wide range of high-quality products here – the right solution for every challenge.

Request a free sample now

Get your desired product sample free of charge by filling out our request form. Our team is happy to help!

Rubber-metal elements combine vibration isolation, shock absorption, noise damping or buffering through the solid product combination of rubber and metal. These maintenance-free, easy-to-install components provide impressive damping, cushioning and suspension. As your partner, we offer you a broad standard range as well as customized solutions for areas such as:

Our rubber-metal elements offer an innovative solution for technical systems with high sealing requirements. Where space is at a premium, conventional seals make assembly difficult. We vulcanize seals directly onto metal components in the injection moulding process, which creates a reliable, tool-bound connection. This offers significant advantages in sealing performance compared to freely applied seals.

For example:

The combination of rubber and plastic in our customized connections enables the integration of additional functions into components. Dimensionally stable and filigree rubber parts become dimensionally stable and assembly-safe, which reduces assembly work and possible reworking and lowers quality assurance costs. The custom-made rubber-plastic elements and connections have decisive advantages over metallic materials.

Discussion of alternative solutions to rubber-metal elements, such as the use of plastics or spring systems.

Integration of recyclable materials (certified recyclates) in the production of rubber-metal compounds.

Comparison of the costs of standard solutions compared to customized rubber-metal elements.

Conducting and analyzing studies on the durability and resistance of the products.

Consideration of current advances and innovations in the field of vibration damping technologies.

Case Study

Blog

Blog

Blog

Thomas van der Wardt

Petra Dirlenbach