Innovative solutions for wind turbines

Wind turbines, also known as wind wheels, are becoming ever larger in order to achieve higher energy yields. As the power output of wind turbines increases, so do the demands on rotor blades, towers, gearboxes and, above all, the parts and components themselves. The focus here is on efficiency, functional safety and durability. With our tailor-made high-performance plastics and rubber and plastic parts, we support manufacturers and suppliers in the wind industry to meet these requirements. Our portfolio includes a wide range of components for rotor blade production, nacelles, hubs and tower construction, as well as for transportation and load safety. We manufacture and supply ready-to-use components and complete assemblies, especially for the wind turbine industry. Your advantage: You define the requirements, we supply the precisely fitting and reliable components for your wind turbine – tailored to the highest demands in energy and environmental technology.

Components and materials made of rubber and plastic play a decisive role in the construction and function of wind turbines. Their properties such as flexibility, resistance to weathering and good damping properties make them indispensable materials in many areas of this technology.

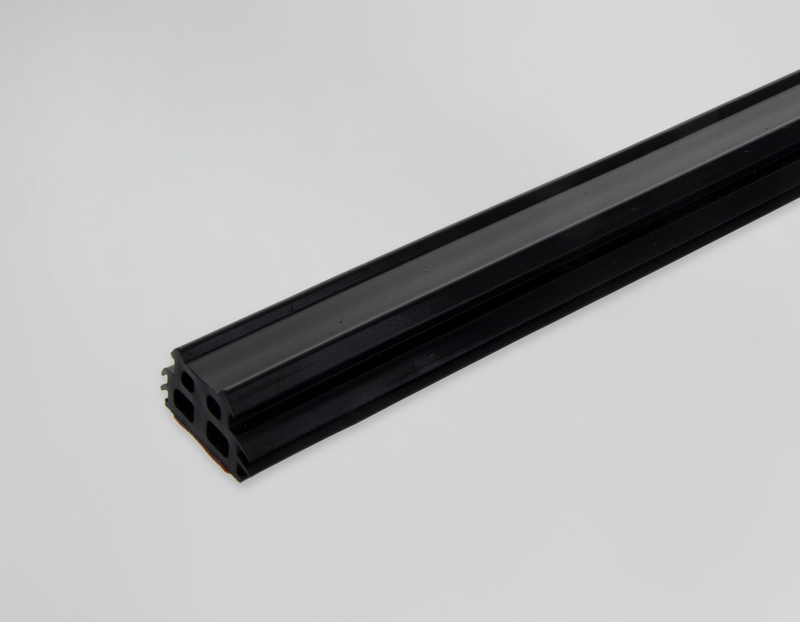

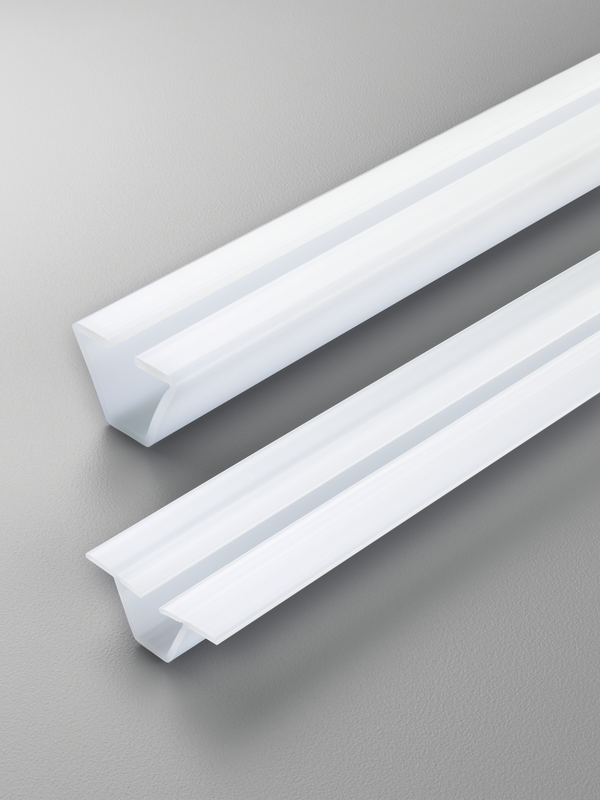

Nose strip protective profiles

Made from flexible polymers, they protect the sensitive leading edge from damage caused by hail or bird strikes.

Seals

Prevent moisture from penetrating the rotor blade and protect the internal structures from corrosion.

Potting compounds

Seal cavities and cable penetrations and protect the electrical cabling.

Bearing bushes

Enable the smooth rotation of shafts and axles, for example in the generator and gearbox.

Seals

Seal off housing parts and prevent lubricants from escaping.

Cable ducts

Enable cables to be fed safely and tightly into the nacelle.

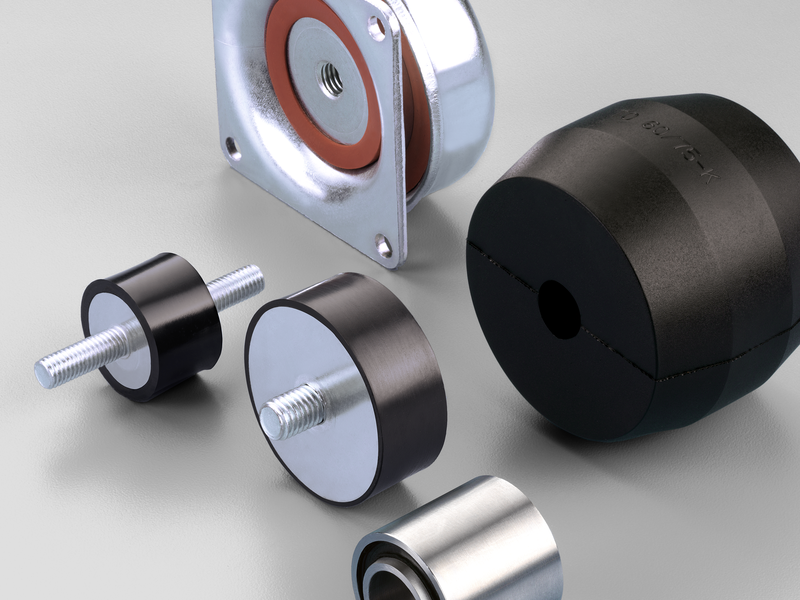

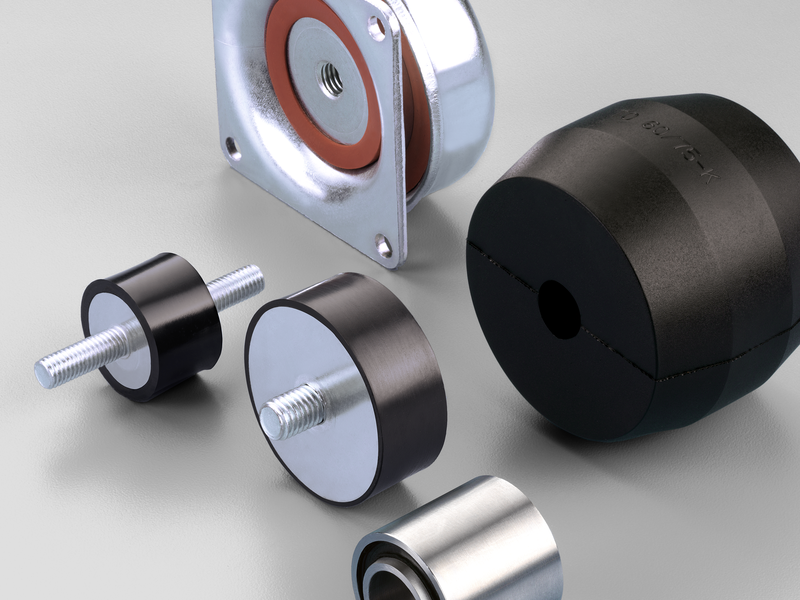

Vibration damper

Reduce vibrations and protect sensitive components.

Seals

Seal joints between tower segments and protect against corrosion.

Cable bushings

Enable cables to be fed safely and tightly into the tower.

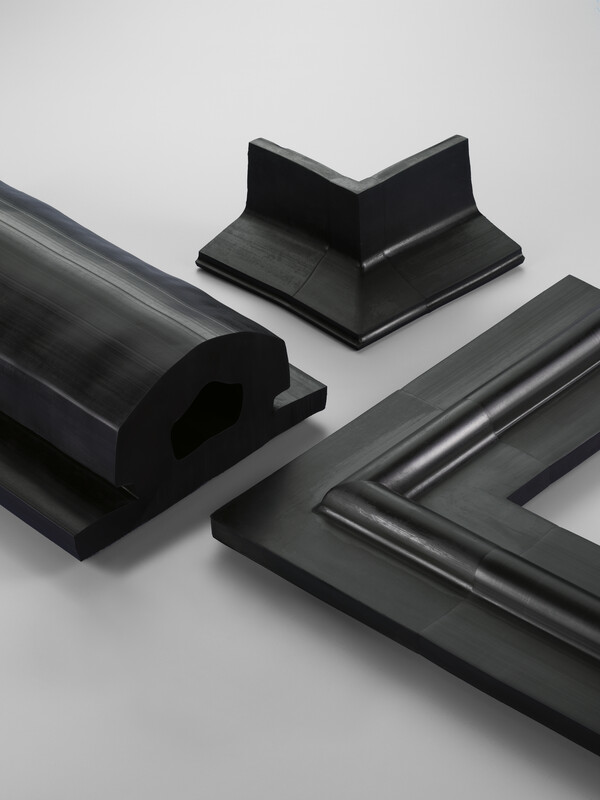

Protective profiles

Protect the surface of the tower from damage.

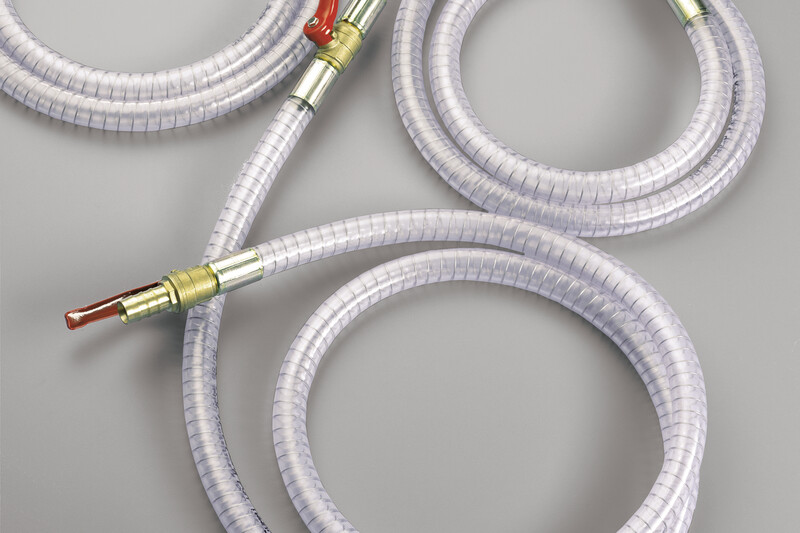

Cable sheaths

Protect electrical cables from mechanical damage, moisture and UV radiation.

Seals

Seal housings of electrical components and protect against moisture.

Molded parts

Serve as brackets, spacers or for fastening components.

Rubber and plastic parts are indispensable components of modern wind turbines, as they fulfill numerous essential functions. Their specific properties make them perfectly suited for use in harsh, demanding environments. But it doesn’t stop there: ongoing innovations in materials and manufacturing processes are constantly creating new applications. We are continuously expanding and advancing the importance of rubber and plastic in the wind energy sector.

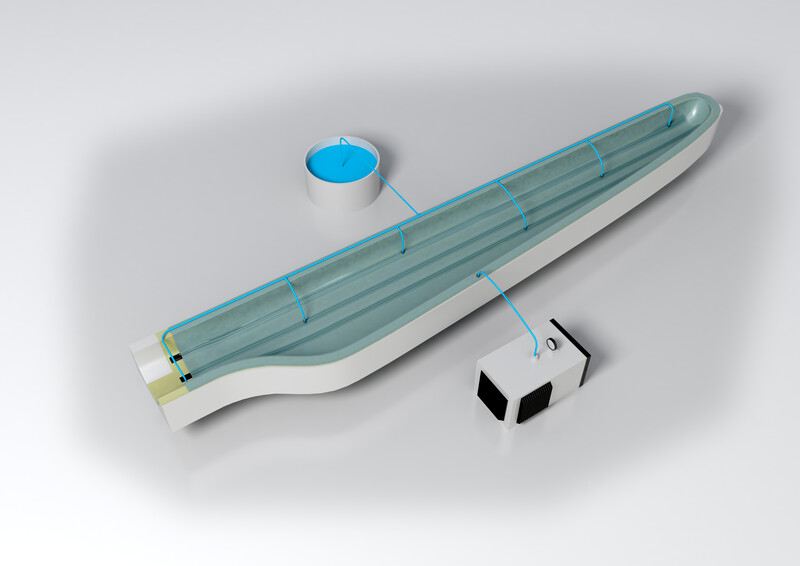

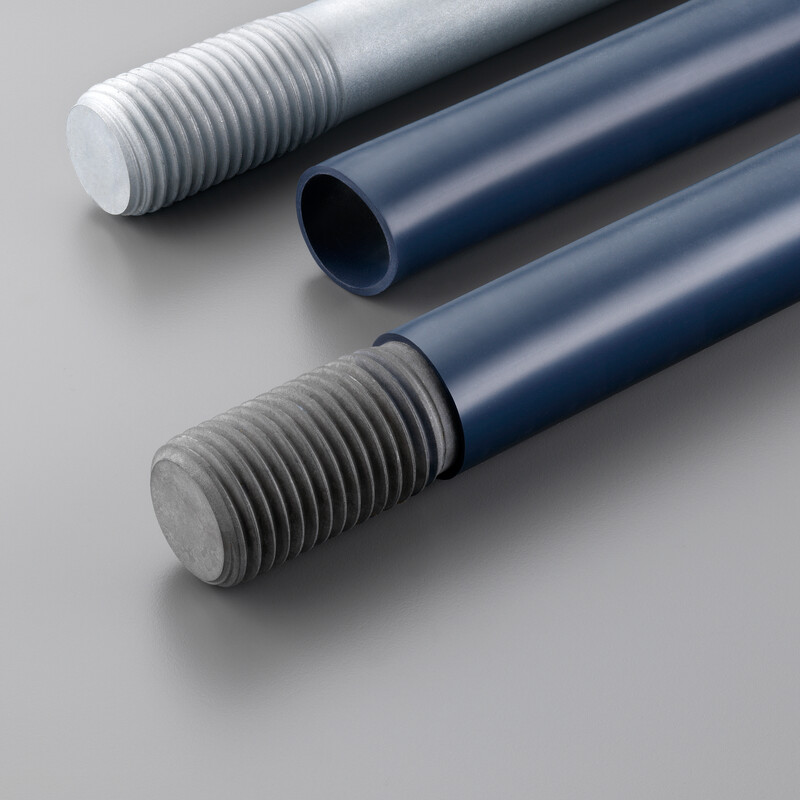

Innovative plastics for durable rotor blades in wind turbines

The rotor blades of wind turbines, which are now over 100 meters long, transmit high forces to the machine set in the nacelle. This poses particular challenges for the design of the components. We offer you a large selection of thermoplastics that are, for example, mechanically high-strength or very dimensionally stable. Our components are safely dimensioned and made from high-quality, tested and proven materials, which are essential for the production of high-performance rotor blades with a long service life.

Products

Products

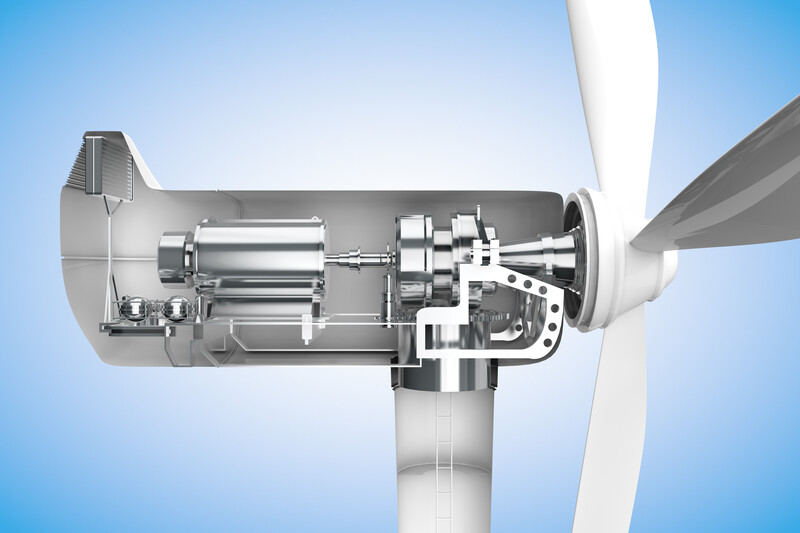

Increased system efficiency thanks to high-quality materials and components

The nacelle of a wind turbine contains the drive train with rotor hub, rotor shaft, generator and other important components. Manufacturers of wind turbines are therefore dependent on reliable materials. These ensure greater system efficiency, longer maintenance intervals and maximum durability.

We provide these with our rubber bearing elements, seals and profiles, which are also suitable for use in rotating parts: for example, they impress with their long service life, low weight and high strength or good noise and vibration-reducing properties.

Products

Application

For protection against dirt, moisture and dust

Products

Products

Special features

Increased system efficiency thanks to high-quality materials and components

The decisive factor for the stability of the entire wind turbine is the tower and its associated elements. These are exposed to extreme loads and environmental influences on a daily basis. Specializing in components for towers of all types, we offer efficient and economical solutions: Our range provides you with durable cable guides and brackets as well as other accessories for fastening and bundling cables in the tower.

Our range also includes platform seals for sealing the gap between the platform and tower wall and pre-assembled modules as well as individual components for sealing tower elements and other components.

Products

Products

Products

Products

Safety and efficiency in the transportation of wind turbine components

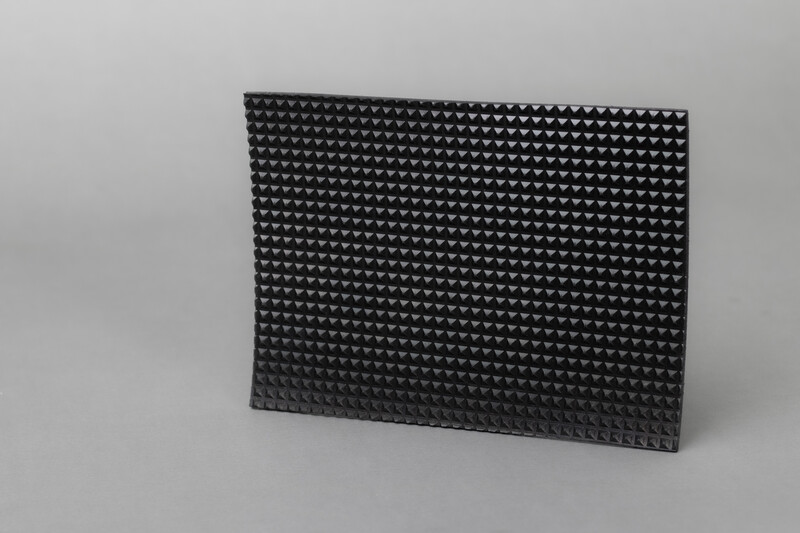

Large components such as towers, rotor blades and rotor hubs are delivered to the construction site in complex transportation steps. In order to secure such components, which weigh several tons, the highest quality care is required to ensure compliance with safety requirements.

We have therefore developed a comprehensive range of efficient and high-quality products and materials for the transport and load securing of components for wind turbines, which can be easily adapted to your requirements and thus enable the safe and professional transport of heavy goods or serve as temporary storage. With our special anti-slip and force-absorbing materials, even extremely heavy components are fully protected during transportation and storage.

Products

Products

Products

Thomas van der Wardt

Petra Dirlenbach