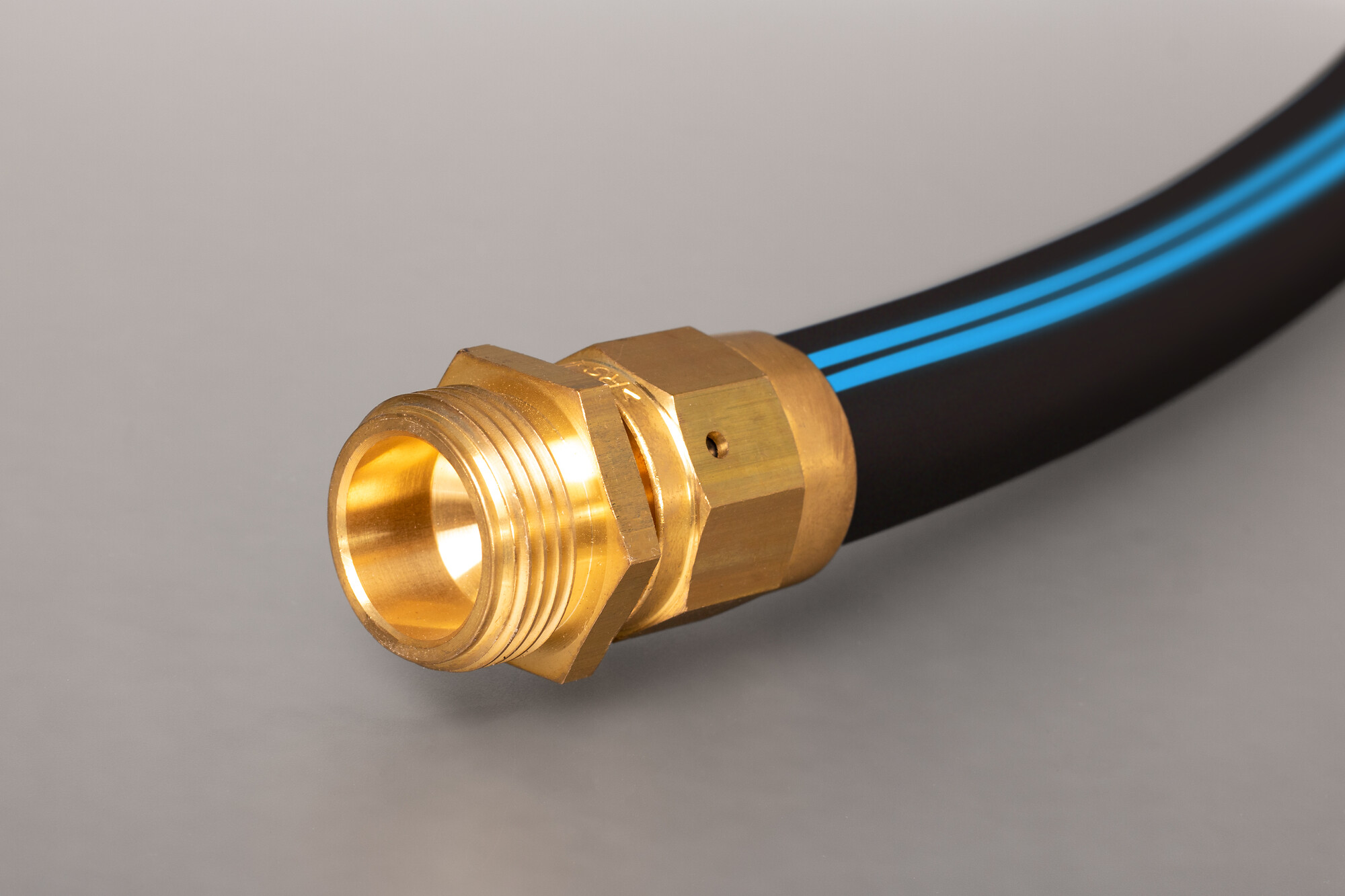

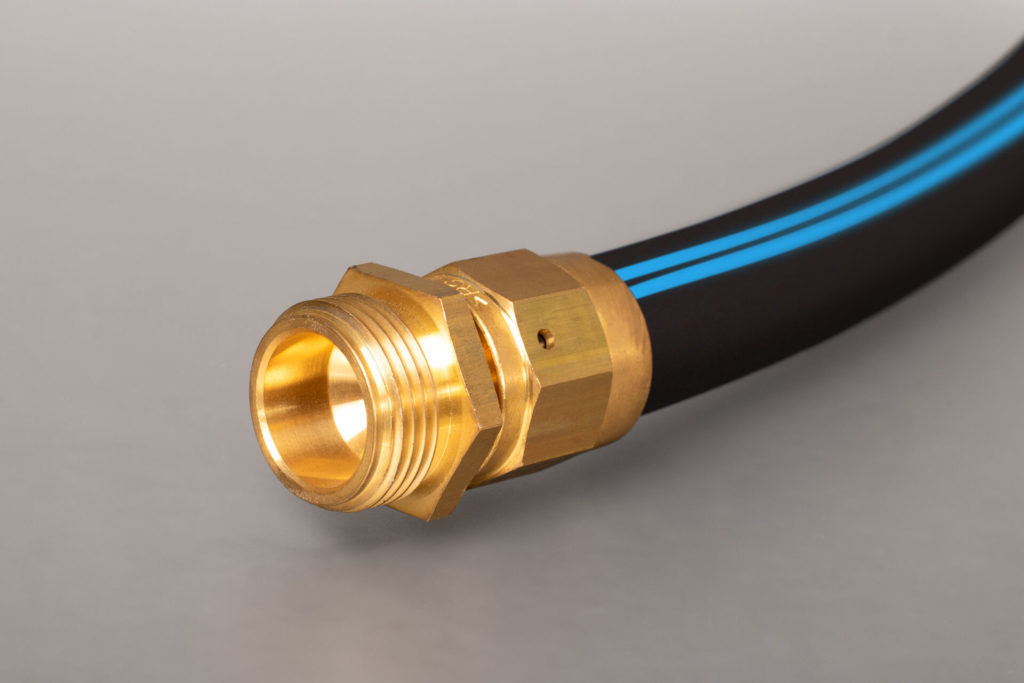

Fasteners with customized application-specific fittings

Quickfacts hoses & hose lines

Application

Materials

Length

Quantity

Manufacture

Dimensions

Fittings

Color

| Application | Flexible connection, transport of media, protection against environmental influences / media leaks |

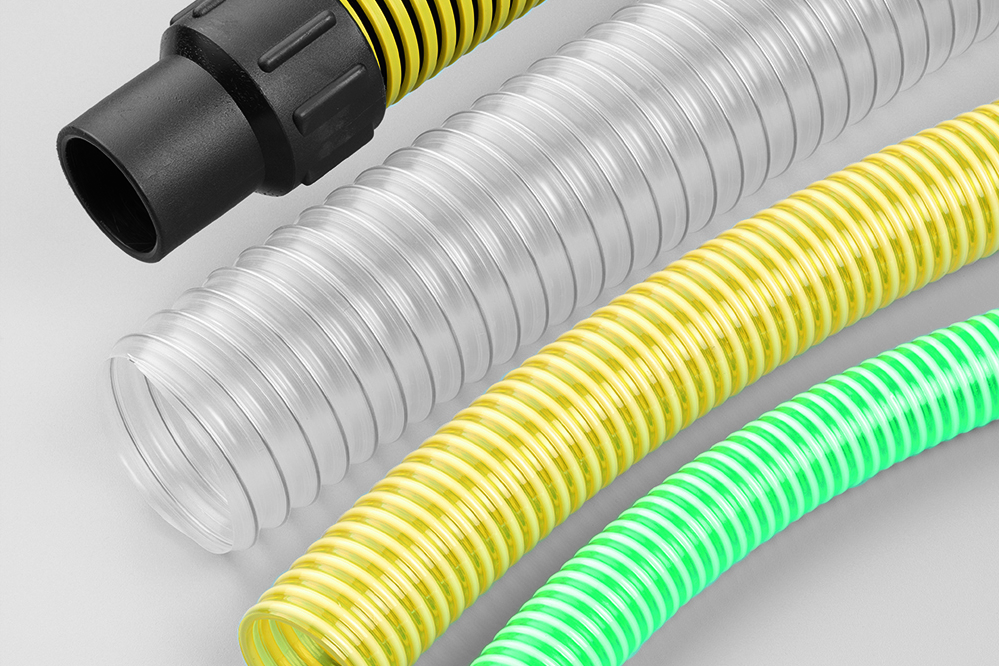

| Materials | Rubber: NR, CR, SBR, silicone, NBR, FKM, EPDM Plastic: PC, PUR, PE, PTFE, PVC, PA |

| Length | Individually customizable |

| Quantity | as of 1 piece |

| Manufacture | Extrusion, co-extrusion, long length, winding process, etc. |

| Dimensions | from 0,5 mm |

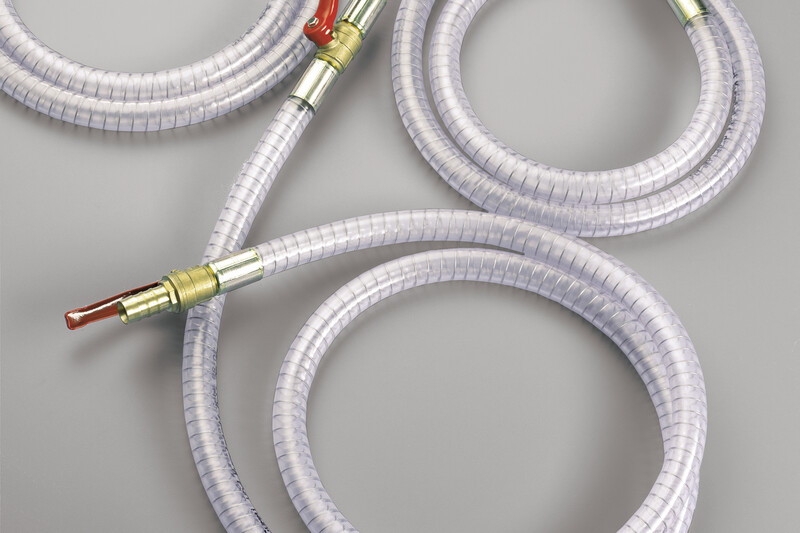

| Fittings | z. e.g. male threaded nipple, sealing cone with union nut, pipe socket |

| Color | Plastic: can be colored as desired, rubber: on request |

Discover our product portfolio now!

Request a free sample now

Get your desired product sample free of charge by filling out our request form. Our team is happy to help!

We offer a comprehensive range of hoses and hose assemblies for various applications: for pressure or vacuum use, in a range of wall thicknesses and lengths, and with or without fittings. This versatility allows for reliable use in agriculture and the food industry (e.g. dairies), as well as in gravel plants, mechanical engineering and pipeline construction. Of course, all of our products undergo pressure and leak testing in accordance with official quality and safety standards – for safe hoses and hose assemblies.

Note: Selecting the right hose depends on numerous factors, such as the medium to be conveyed, the temperature, the pressure, the chemical resistance and the mechanical loads.

Soul

Spiral

Cover

As the modulus of elasticity of rubber and plastic is comparatively low, hoses are fitted with inserts to reinforce them if they are to be subjected to higher operating pressures. The different selection and number of inserts are determined almost exclusively by the required pressure rating.

Insert

The sensitive strength members and inserts are protected from external influences by the hose cover. The right choice of material determines the resistance to abrasion, media attack and weathering and is therefore decisive for the service life.

Brochure

The next generation of the extremely abrasion-resistant Semperit SIGMA® conveyor system for the hydraulic and pneumatic pneumatic transport of abrasive media comprises three different products.

Blog

Blog

Blog

Blog

Thomas van der Wardt

Petra Dirlenbach