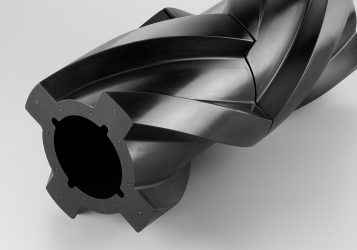

Innovative rubber-plastic compounds for demanding applications

Customized rubber-plastic elements represent a revolutionary technical solution in areas where individual materials reach their limits. Jäger Gummi und Kunststoff GmbH specializes in the development of directly connected rubber and plastic components and joints that combine the advantages of both materials. This synergetic combination of customized rubber and plastic elements opens up a wide range of possible applications for simple and complex assemblies for a wide variety of industrial requirements.

Quickfacts Rubber-plastic elements

Application

Materials

Variations

Hardness

Manufacture

CM, TM, IM, Extrusion

Connection

Colors

| Application | Damping, sealing, insulating, protecting, etc. |

| Materials | Elastomers: NR, SBR, IR, BR, NBR, EPDM, CR, ECO, ACM, silicone Thermoplastics: PA, POM, PET, PC, PPE, PVC, PE, PP, PEEK, PPS, PSU, PUR, TPE, ABS, PC/ABS, PBT, ... |

| Variations | Individual components or (ready-to-install) assemblies |

| Hardness | 20 ± 5 Shore A to 90 ± 5 Shore A (rubber component) |

| Manufacture | CM, TM, IM, Extrusion |

| Connection | Chemical-physical direct composites |

| Colors | Customized |

Discover our range of products now!

You will find a wide range of high-quality products here – the right solution for every challenge.

Request a free sample now

Get your desired product sample free of charge by filling out our request form. Our team is happy to help!

Our expertise focuses on chemical-physical direct composites between thermoplastics and elastomers as well as on thermoplastic elastomers (TPE). Direct injection molding of the elastic component onto the thermoplastic body without prior priming can significantly reduce costs. Our rubber-plastic compounds not only meet the strict requirements for food and drinking water (FDA, BfR, etc.), but also the demanding specifications of the electrical industry. The choice of manufacturing process depends on various factors, such as the desired product quality, the complexity of the geometry, the required quantity and the materials to be used. By combining different processes and materials, we can manufacture extremely diverse and high-performance products for you.

The combination of rubber and plastic in our customized connections enables the integration of additional functions into components. Dimensionally stable and filigree rubber parts become dimensionally stable and assembly-safe, which reduces assembly work and possible reworking and lowers quality assurance costs. The custom-made rubber-plastic elements and connections have decisive advantages over metallic materials.

Discussion of alternative solutions to rubber-metal elements, such as the use of plastics or spring systems.

Integration of recyclable materials (certified recyclates) in the production of rubber-metal compounds.

Consideration of current advances and innovations in the field of vibration damping technologies.

Conducting and analyzing studies on the durability and resistance of the products.

Comparison of the costs of standard solutions compared to customized rubber-metal elements.

We manufacture your molded rubber parts to the highest quality standards according to your specifications. At our various production sites worldwide, we have access to over 26 compression and transfer molding machines with maximum clamping dimensions of up to 700 x 700 mm and clamping forces of up to 3,500 KN.

Our 17 injection molding machines with max. clamping dimensions of up to 1,000 x 1,200 mm and clamping forces of up to 10,000 KN complete our machine park in rubber moulding production.

Modern liquid silicone injection molding machines (up to 3,000 KN) including professional cold runner technology complete our process portfolio at our German headquarters. The production of molded parts from solid silicone (HTV) is also an integral part of our process landscape.

Special tasks require special solutions:

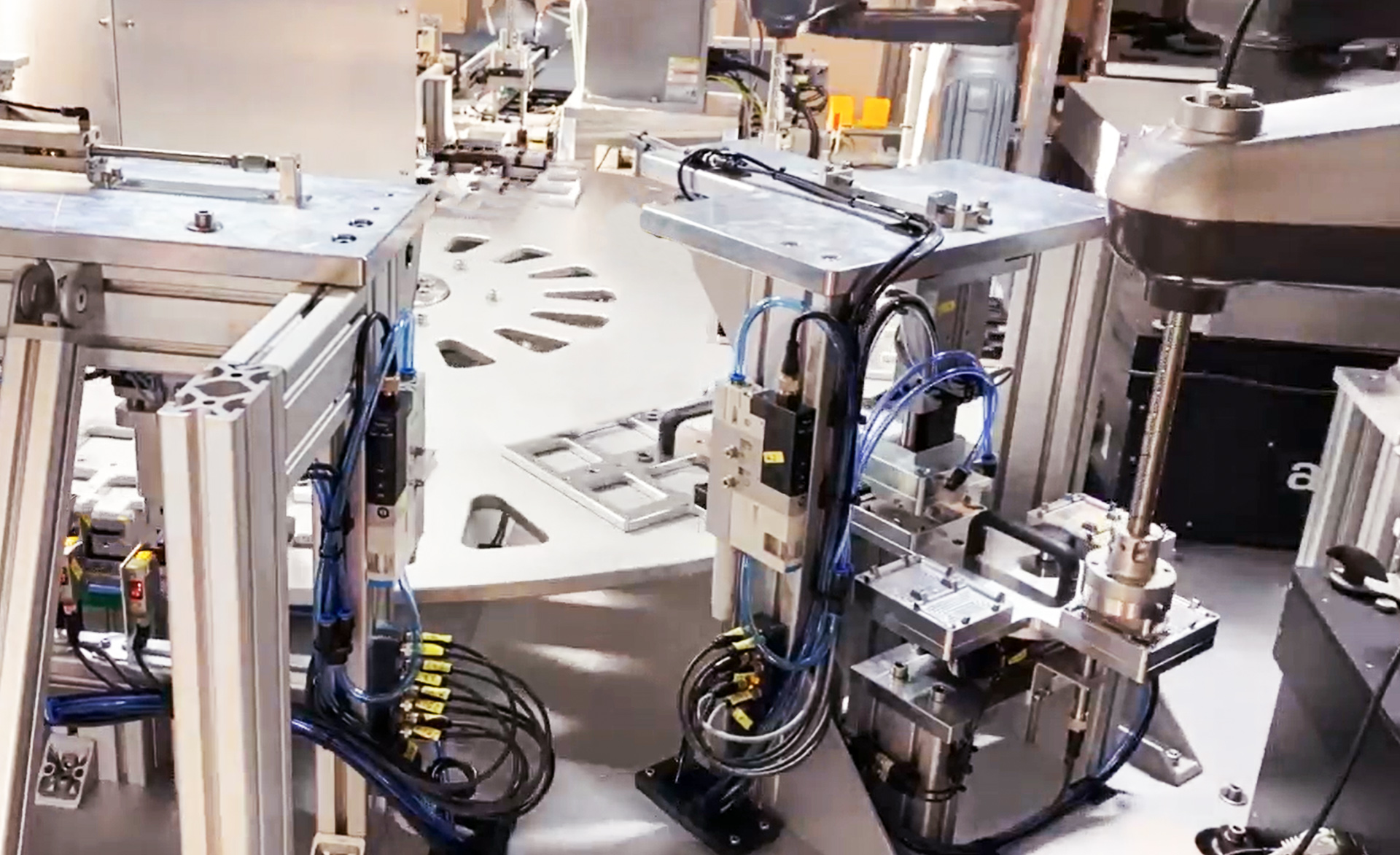

We realize partially and fully automated, robot-supported assembly systems for our customers. We mainly use components that originate from previous production processes. To ensure that quality requirements are met, the use of optical measuring systems guarantees 100% inspection of relevant product features. End-to-end traceability is ensured by the application of Data Matrix codes.

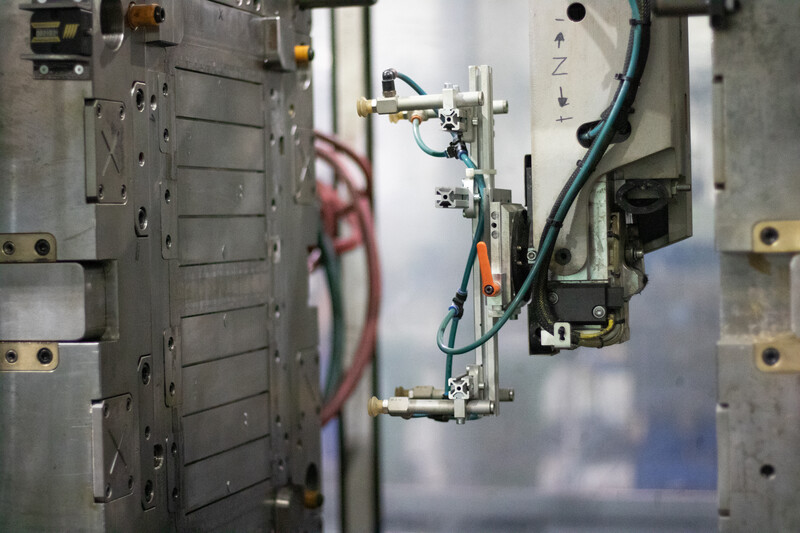

We use injection molding to produce your plastic moulded parts according to customer-specific drawings or CAD data. Thanks to the unique properties of the process and material, complex geometries can be realized. With 14 machines worldwide with clamping forces of up to 4,500 KN, removal and assembly robots, Jäger Gummi und Kunststoff GmbH has state-of-the-art production capacities. We can handle requirement profiles of up to 25,000 KN with our production partners.

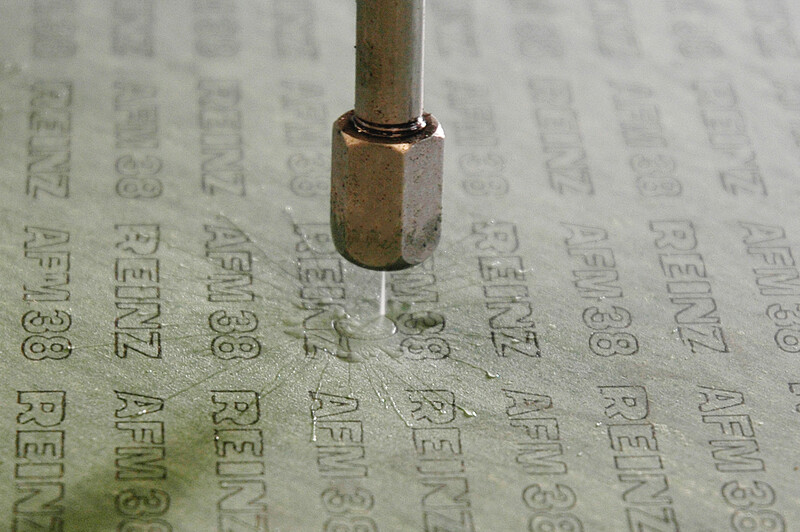

Whether classic punching or plotting of your products with maximum precision or the targeted separation of materials on a carrier film without penetrating it using the kiss-cut process. Waterjet cutting also enables the precise separation of materials without the need for a tool. We offer you the technologies and know-how to implement your ideas.

Case Study

Case Study

Blog

Rubber and metal are important components of industrial products. Knowing their differences and similarities is essential for design.

Blog

Intelligent product design in the rubber and plastics sector offers a wide range of opportunities to reduce a company’s CO2 emissions.

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dipl.-Ing Sebastian Jäger

Julius Jäger, M.Sc.

Hanover Register Court HRB 59798

DE 813 314 161

Petra Dirlenbach